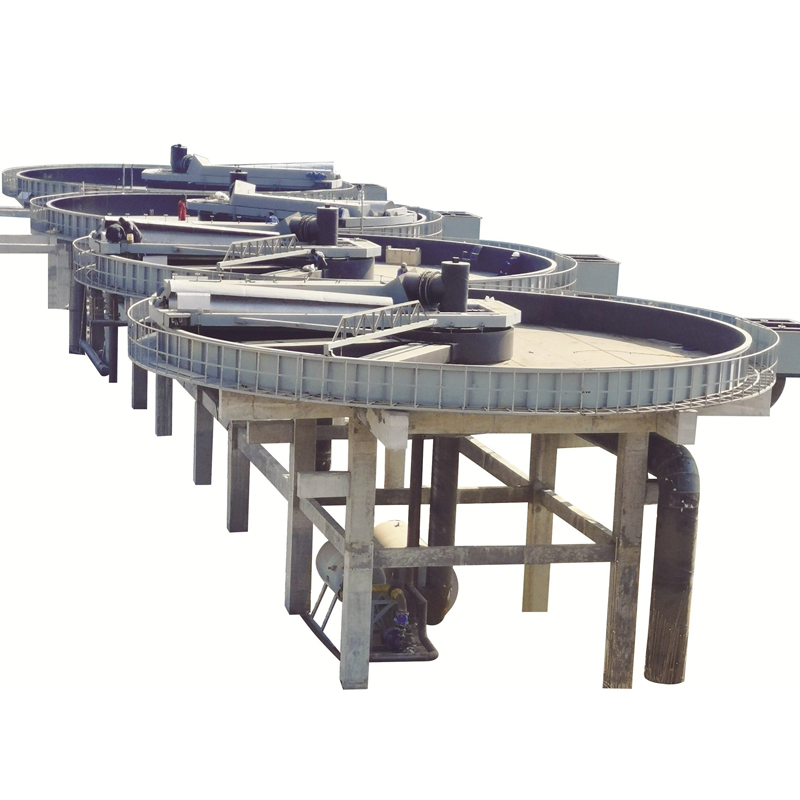

Traveling Scraper And Sludge Sucker

product picture

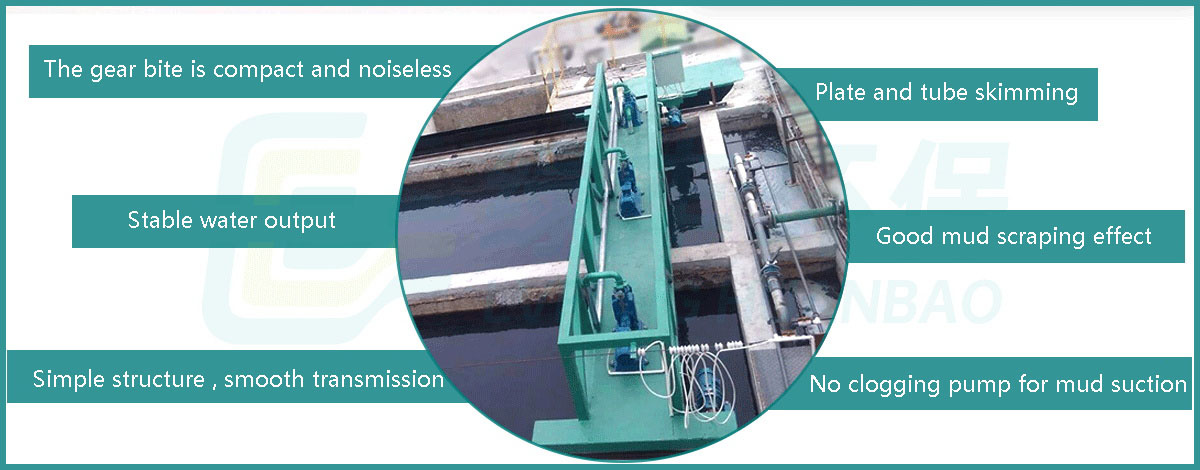

Features

This machine has a compact structure, reliable operation, and is equipped with an automatic control and overload protection system. The mud suction machine adopts a centralized drive in the middle when the track spacing is less than 4 meters. When the track spacing is more than 6 meters, it uses synchronous drive at both ends. It has clean mud discharge, high efficiency and high cost performance. Features.

1. The submersible non-clogging pump is used to suck mud, which can operate at full lift, has good performance and is light in weight. It overcomes the past defects of submersible pumps such as wear and difficulty in installation and maintenance due to the long shaft length that easily causes vibration;

2. Using a small-capacity submersible sewage pump, a mud suction system with only one mud suction nozzle for each pump can be realized. Therefore, even if there is a water supply process arrangement with a longitudinal outlet channel and its buttresses at the outlet end of the sedimentation tank, the mud suction machine can still pass unimpeded, ensuring the mud discharge effect throughout the entire length;

3. The pump/siphon dual-purpose mud suction machine saves water and energy: In a sedimentation tank with siphon mud discharge conditions, the position difference between the water outlet weir and the mud discharge port can also be fully utilized, and the submersible sewage pump is cut off after the submersible sewage pump starts to discharge mud. The power supply is converted from pumping to siphoning, which not only saves water and energy but also eliminates the need for system evacuation devices;

4. Since there is no need for vacuuming equipment, it is easy to operate and easy to realize automated program control management;

5. The main beam structure is reasonable. For large-span advection sedimentation tank mud suction machines, truss type or "L"-shaped composite beams are used; for medium- and small-span inclined tube tank mud suction machines, single or double-tube beams and profiled steel beams are used; In particular, the mud suction pipe in the inclined tube sedimentation tank serves as both a channel and a load-bearing component, so it saves materials and is easy to manufacture and maintain.

6. New transmission devices are optional. The key components of the drive device adopt new product shaft-mounted or flange-mounted gear reducers, which have large load-bearing capacity and eliminate the need for couplings. Compact structure, high efficiency and light weight.

7. It is mainly driven by aligned transmission gears, and the gear meshing gap is compact and noise-free;

8. There are two methods of skimming: plate skimming and tube skimming;

9. The reducer is equipped with an over-torque protection device, making the operation safe and reliable;

10. The mud suction pipe adopts horizontal perforated pipe method to discharge mud, which has no interference in the pool and ensures the stability of water discharge;

11. The inlet and outlet tanks around the sedimentation tank are designed with edge sections to ensure uniform water distribution and outflow around the sedimentation tank;

12. It has a simple structure, stable transmission, low operating cost and good mud scraping effect. It is an ideal mud discharge equipment.

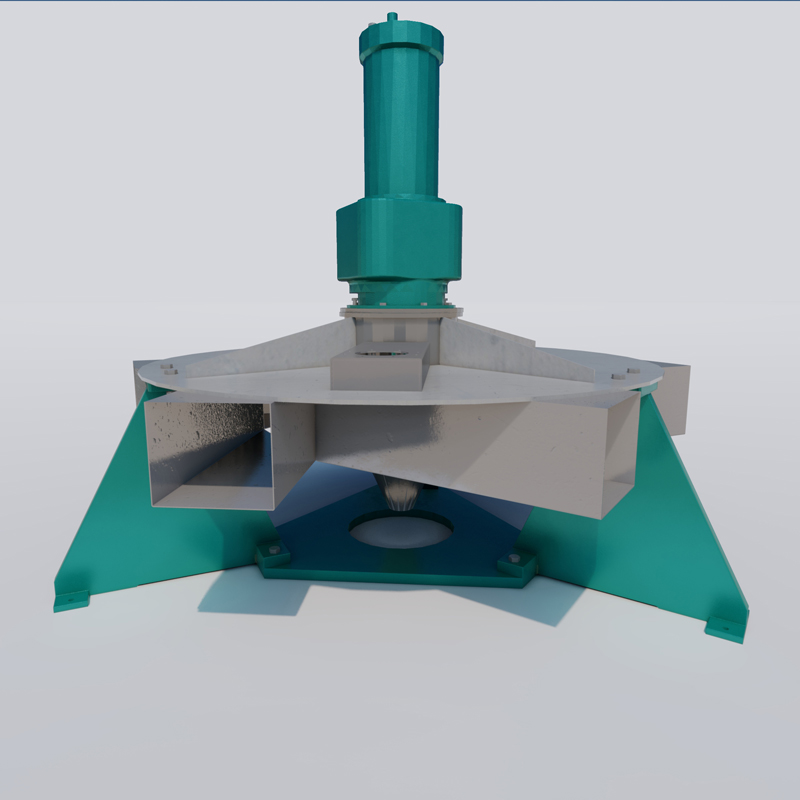

Working Principle

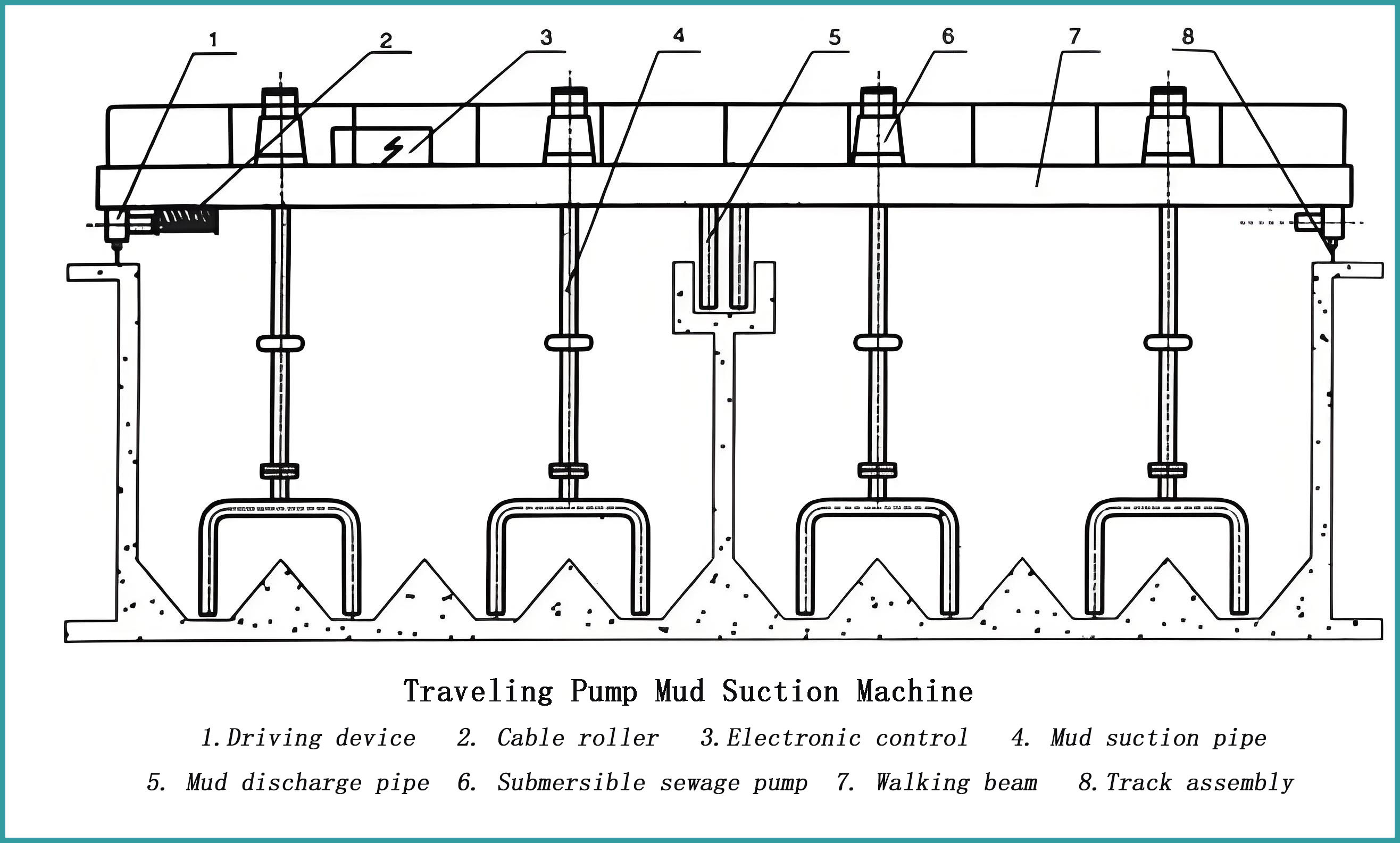

The traveling mud scraper is mainly composed of transmission device, driven shaft device, driving shaft device, adjusting device, bracket, electric control box and other components. The driving devices on the beams at both ends of the main beam serve as the power source and drive along the track laid on the top of the pool. The submersible sewage pump moving with the main beam absorbs the sludge deposited at the bottom of the pool and discharges it through the mud pipe. (The scraper and the traveling motor perform their own duties during operation without interfering with each other. The bottom of the scraper is equipped with an underwater traveling wheel structure to ensure smooth operation. The two traveling motors use synchronous motors to ensure that both sides The walking is consistent and smooth.) When the sedimentation tank with siphon conditions (the distance between the sedimentation tank outlet weir and the mud discharge outlet is not less than 3m) and the power is cut off after the submersible sewage pump starts to discharge mud, the mud discharge mode can be switched from pumping to siphon; not required When the mud discharge is stopped, the cut-off valve can be opened, and a large amount of air will enter the mud conveying pipe, the siphon will be damaged, and the mud discharge will be interrupted.

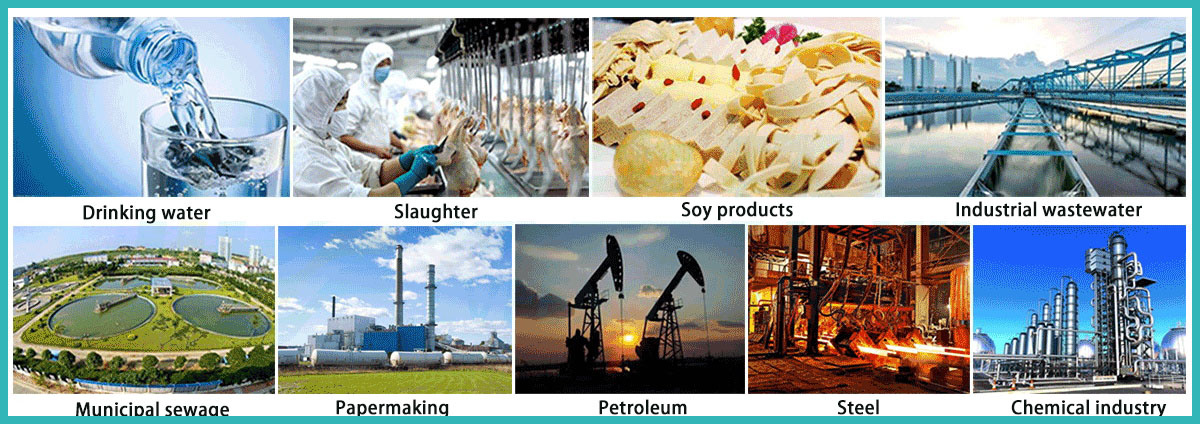

Application Scope

1. Used in papermaking, slaughtering, leather, sugar, wine, food processing, textile, printing and dyeing, petrochemical and other industrial wastewater treatment, remove suspended matter, floating matter, sediment and other solid matter;

2. Used in papermaking, alcohol, starch, food processing and other industries in the recovery of fiber, slag and other useful substances;

3. Used in urban sewage treatment instead of the initial sedimentation tank.