Integrated sewage treatment equipment

Introduction

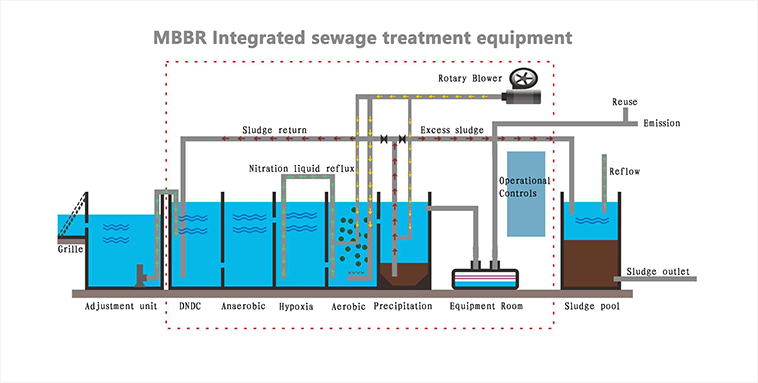

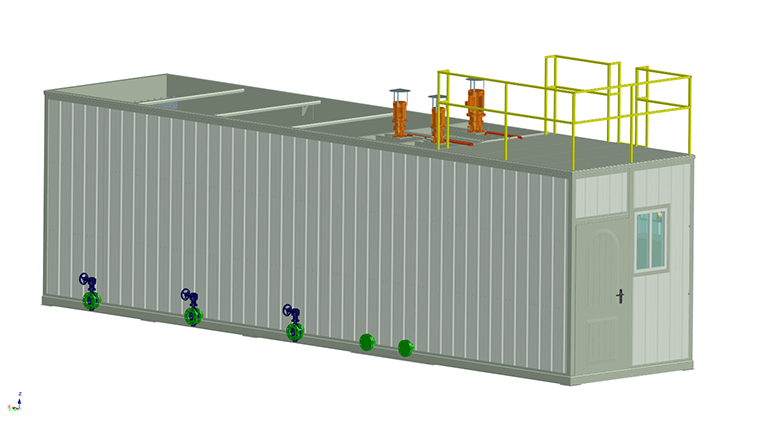

Integrated sewage treatment equipment is a device that integrates anoxic tanks, anaerobic tanks, aerobic tanks, sedimentation tanks, sludge tanks, disinfection tanks, equipment rooms, etc., and performs aeration in the aerobic tank to effectively combine the contact oxidation method and the activated sludge method. It has the advantages of both and overcomes the disadvantages of both, so that the sewage treatment level is further improved. The main purpose of the integrated machine is to make small-scale domestic sewage and similar industrial wastewater meet the discharge standards required by users after being treated by the equipment.

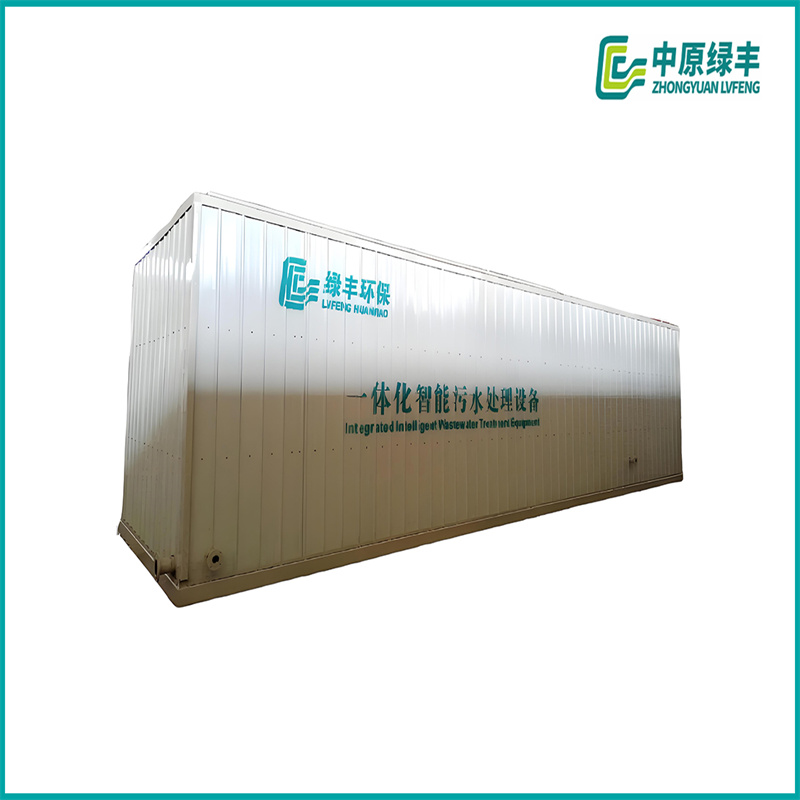

The integrated machine can be placed on the ground or buried underground; the appearance is ever-changing and is suitable for different spatial terrains, as well as residential areas, villages, office buildings, hotels, schools, factories, tourist attractions, etc. Domestic sewage and similar small-scale industrial organic wastewater such as slaughtering, aquatic product processing, and food are treated.

Features

The integrated sewage treatment equipment eliminates the air compressor, avoiding the noise pollution caused by the air compressor; cancels the operation and maintenance of the air compressor, reduces the treatment cost, and further improves the flotation effect.

The integrated sewage treatment equipment has a reasonable design, compact structure, small footprint, low energy consumption, and stable treatment effect. Therefore, it requires less investment and has a quick effect. It is an economically ideal sewage treatment equipment.

1. It can be installed on the ground or buried underground. It has a modular design, compact structure, small footprint, space saving, and can be specially arranged according to the terrain.

2. Low noise, less odor, and little impact on the surrounding environment.

3. High work efficiency, mature technology, and investment saving.

4. High degree of automation, convenient management, and no need for special management.

5. Reliable technology, stable water quality when draining sewage.

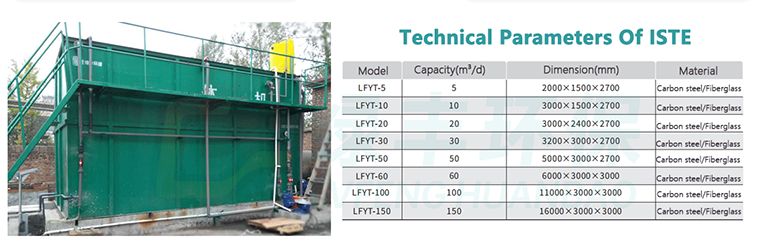

6. It can be made of carbon steel, stainless steel, fiberglass and other materials, with beautiful appearance, good anti-corrosion performance and long service life.

7. Short processing and production period, fast installation and construction.

Working Principle

The integrated sewage treatment equipment adopts the currently more mature biochemical treatment technology contact oxidation method, which is mainly used to treat domestic sewage and similar industrial organic sewage. In the hydrolysis section, the easy-to-cultivate bacteria hydrolyze the suspended pollutants such as starch, fiber, carbohydrates and soluble organic matter in the sewage into organic acids, decompose the macromolecular organic matter into small molecular organic matter, and convert the insoluble organic matter into soluble organic matter. When these products of anoxic hydrolysis enter the aerobic pool for aerobic treatment, the biodegradability of the sewage and the efficiency of oxygen can be improved; in the anoxic section, heterotrophic bacteria ammonify pollutants such as proteins and fats (N on the organic chain or amino groups in amino acids) to release ammonia (NH3 ammonia, NH4 + ammonium cations). Under sufficient oxygen supply conditions, the nitrification of autotrophic bacteria oxidizes NH3-N ammonia nitrogen (NH4 + ammonium cations) to NO3- (nitrate), which is returned to pool A through reflux control. Under anoxic conditions, the denitrification of heterotrophic bacteria reduces NO3- (nitrate) to molecular nitrogen (N2) to complete the cycle of C, N, and O in the ecology, and realize pollution-free sewage treatment.

Generally speaking, it is divided into two processes: physical and biochemical. In the initial stage, filtration and sedimentation are performed; then, according to the different types of sewage, neutralizing agents, flocculants, biological treatment aeration and anaerobic treatment are added.

Taking domestic sewage as an example, the water quality of the integrated machine inlet can be calculated as: COD 350 mg/l, and the water quality of the outlet can be calculated as: COD 50mg/l.

Technical Data

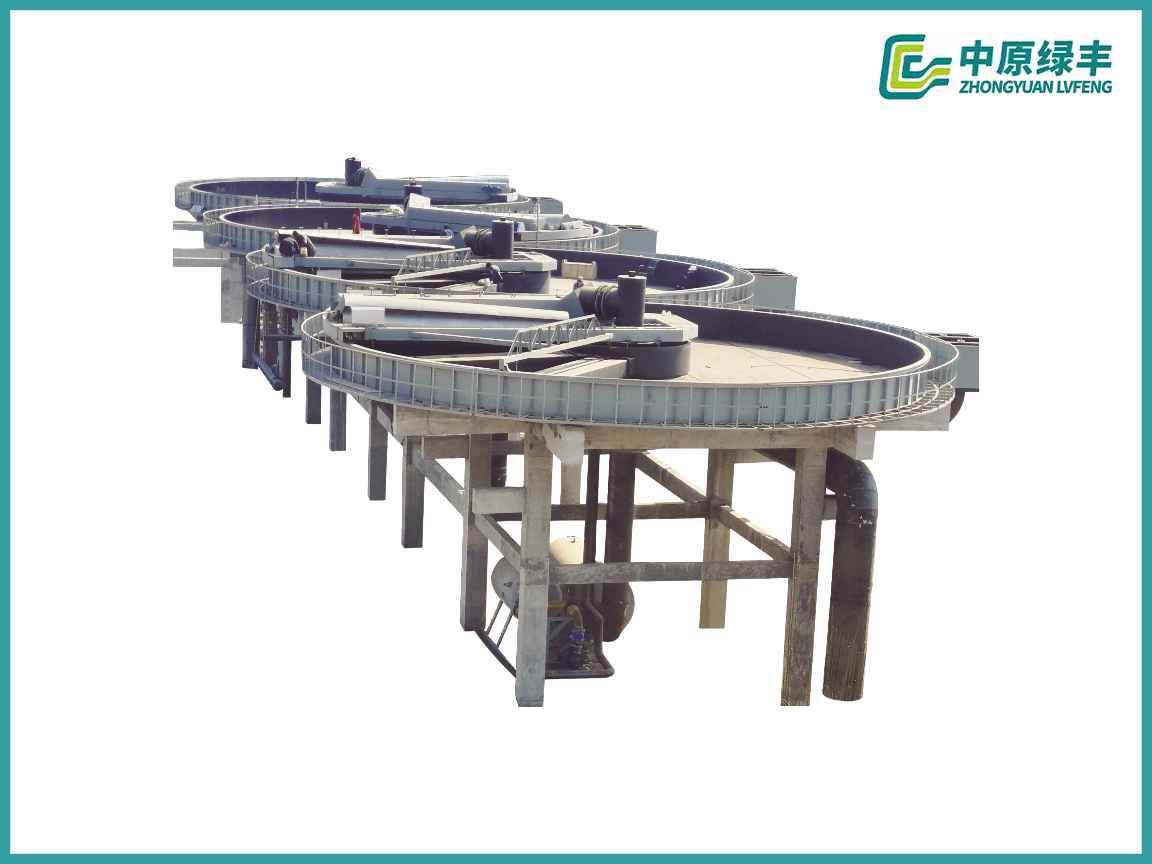

It consists of six parts: (1) hydrolysis acidification tank; (2) contact oxidation tank; (3) secondary sedimentation tank; (4) disinfection tank, disinfection device; (5) sludge tank; (6) fan room

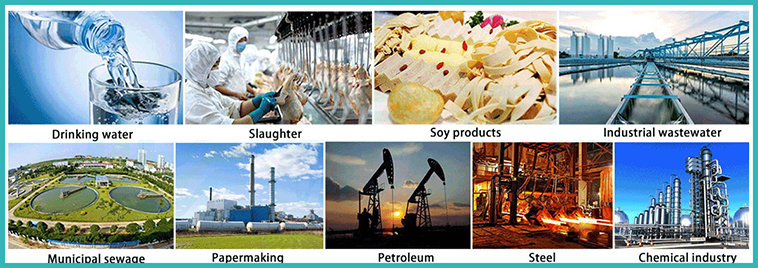

Application Scope

1.used in papermaking, slaughtering, leather, sugar, wine, food processing, textile, printing and dyeing, petrochemical and other industrial wastewater treatment, remove suspended matter, floating matter, sediment and other solid matter;

2.used in papermaking, alcohol, starch, food processing and other industries in the recovery of fiber, slag and other useful substances;

3.used in urban sewage treatment instead of the initial sedimentation tank.